Planning and line building business

Planning that shapes your needs

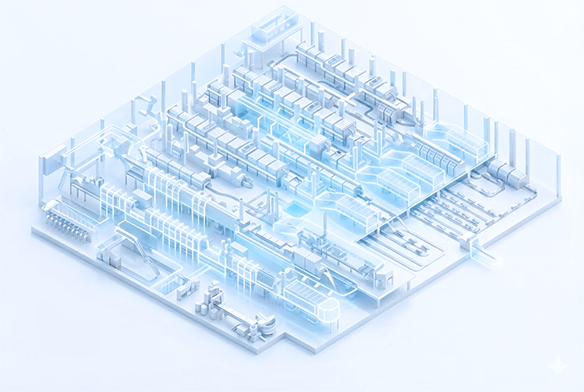

Taikisha's Paint System Division is a total solution partner that realizes the overall optimization of your painting system. We do not just provide equipment, but also handle planning from the concept stage, equipment selection, line design, control, automation, installation, and trial operation to build the optimal painting system.

Our strength is planning ability rooted in the essence of the process. We present optimal solutions that balance space, processes, and equipment, taking into account the characteristics of the product to be painted, production conditions, safety standards, and future scalability. This makes it possible to realize a line that takes into consideration the coordination between equipment, maintainability, and stable productivity.

In addition, during the design phase, we make specific proposals that are in line with the site by using 3D-CAD to design the layout and consider traffic flow. If necessary, we perform simulations to check the operation and process balance in advance, supporting smooth transitions at the start-up and highly stable operation.

We provide lines that combine optimal equipment configuration and automation technology, focusing on the delicate and highly specialized process of painting, to achieve both precision and efficiency in manufacturing. That is Taikisha's Paint System Business.

01

Painting equipment planning

Taikisha's painting equipment planning, supported by experience and technical capabilities

Taikisha has accumulated numerous achievements in painting equipment planning, and provides optimal solutions according to the conditions and challenges of manufacturing sites. We contribute to the efficiency of the painting process, stabilization of quality, and cost reduction, and produce solid results.

Main features

- 1.Customized design: Taikisha customizes and designs painting equipment according to the specific requirements of each customer. This allows us to build a painting system that is optimal for the characteristics of the product and the conditions of the production line.

- 2.Process optimization: We analyze the entire painting process in detail and propose the optimal painting method and equipment layout. This maximizes the efficiency and quality of painting and minimizes waste in the process.

- 3.Introduction of the latest technology: By introducing cutting-edge painting technology and automation systems, we automate and improve the accuracy of the painting process. This enables uniform, high-quality painting finishes.

- 4.Environmental considerations: We plan environmentally friendly painting equipment, including energy-efficient system designs, with the aim of reducing the burden on the environment.

Taikisha's painting equipment planning supports innovation in the painting process in the manufacturing industry, and is a reliable partner for improving production efficiency and painting quality.

02

Line Build Business

Entering the line build business centered on automation technology

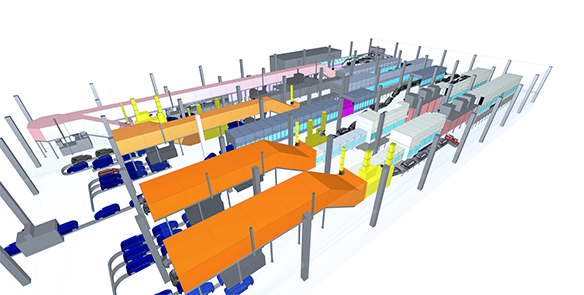

Taikisha's line build business uses digital and automation technologies such as 3D design, simulation, robotics, and transport systems to carefully visualize the line from the planning stage to its state after operation.We check information such as input amount, takt time, and equipment load in advance and consider the optimal layout with an eye toward actual operation.

This allows for reasonable equipment planning and process design that is tailored to the customer's site conditions, contributing to the construction of an efficient production line.We also make proposals based on reliable data for issues such as improving quality, reducing labor, and improving safety, and support the creation of a line that can operate stably and accommodate future expansion.

03

Simulation Technology

Optimal equipment and process design through advanced simulation (various simulations and analyses)

Taikisha combines a variety of simulation and analysis technologies in the fields of air conditioning, process design, automation, and structural design to propose optimal facility plans and production processes.

Based on the visualized analysis results, we propose optimal equipment specifications that simultaneously achieve energy savings, high quality, and stable production.

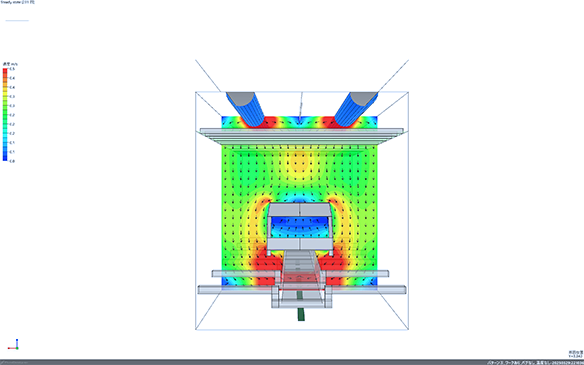

Air conditioning analysis (CFD)

We visualize airflow and temperature environments in advance and provide easy-to-understand suggestions for optimal air conditioning specifications and energy-saving effects.

Heat conduction analysis

We will identify temperature variations and thermal stress in booths, ovens, etc. in advance and propose improvement measures that will lead to stable operation and energy savings.

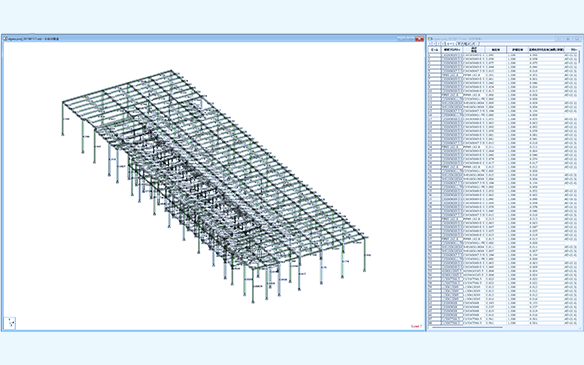

Structural analysis (buildings/machines)

From facilities and equipment to large structures such as booths and ovens, we comprehensively evaluate the strength, rigidity, heat resistance, and earthquake resistance of all our equipment, and propose safe and reliable structures that can withstand long-term operation.

Robot operation and process review

We reproduce the robot's movement trajectory, posture, and interference, and propose waste-free process designs and optimal layouts.

Line Simulation

We will "visualize" the flow of the entire line and propose the optimal line configuration.

04

3D-CAD

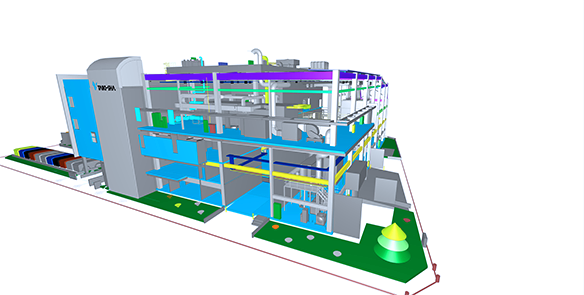

By combining accurate facility design using BIM with simulations that utilize models, we provide facility plans that are easy to understand, reliable, and efficient.

Taikisha offers high-quality solutions that utilize 3D models, from the design stage to construction and operation.

① Facility design using BIM

Taikisha integrates buildings, equipment, piping, and transportation using BIM, making facility plans three-dimensionally visible. BIM allows us to check the layout, fit, interference points, and even construction and maintenance spaces in advance, enabling us to make highly accurate proposals from the planning stage.

Even in meetings with customers, it is easy to share complex equipment configurations that are difficult to convey through drawings, and it is a feature that consensus building proceeds smoothly. We provide reliable and efficient equipment plans that reduce rework.

② Validating production lines using 3D models

3D models are also used to verify production lines. By checking the robot's operating range, transport flow, workspace, production takt time, etc. in advance through simulation, the "movement" and "efficiency" of the entire line can be understood before the actual equipment is introduced.

This allows us to optimize robot placement, ensure safety, and quickly identify areas for improvement to improve productivity, allowing us to propose a lean line configuration.

Preliminary verification using 3D models leads directly to the creation of a more reliable and competitive production line.

Contact

For inquiries or questions regarding this website,

please click on this button.