Process Business

High-quality, environmentally friendly painting equipment solutions

Taikisha provides painting systems to customers in a wide variety of industries, including automobiles, construction machinery, and aircraft.

We not only design, manufacture, and install painting systems to realize efficient painting processes, but also provide environmentally friendly painting equipment solutions, such as energy-saving painting booths and drying ovens, that contribute to a decarbonized society.

Automobiles

01

Pretreatment/Electrodeposition Equipment

Pretreatment

Taikisha's pretreatment is an important process for cleaning oil and dirt from metal surfaces with high precision and stabilizing the adhesion of paint, the quality of the coating, and the finish.

Taikisha optimizes energy efficiency and wastewater treatment through technical design that reduces the impact on the environment. In addition, the equipment can be customized to suit a variety of products and line configurations, so it is used at many sites.

Electrodeposition

Taikisha's electrodeposition equipment achieves a uniform, high-quality anti-rust coating film, enabling a finish with excellent durability, adhesion, and beauty.

The unique countercurrent circulation method (C-FLOW) achieves uniform coating film formation even on complex shapes.

With high technical capabilities and equipment design, it is a reliable electrodeposition solution with a proven track record.

Technology List

02

Booths and air conditioners

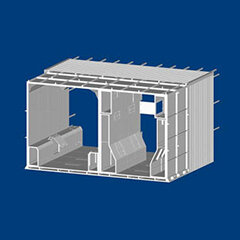

Booths

Taikisha's painting booths are equipped with temperature and humidity control required for the painting process and a high-performance ventilation system, which effectively expels dust and VOCs generated during painting. This ensures a safe working environment while supporting high-quality paint finishes.

We can design the booth according to the installation environment, work content, and type of paint to be handled, and can design the optimal specifications to meet various needs.

Based on our extensive implementation track record, we can flexibly meet the needs of a wide range of industries and products with customization that combines functionality and reliability.

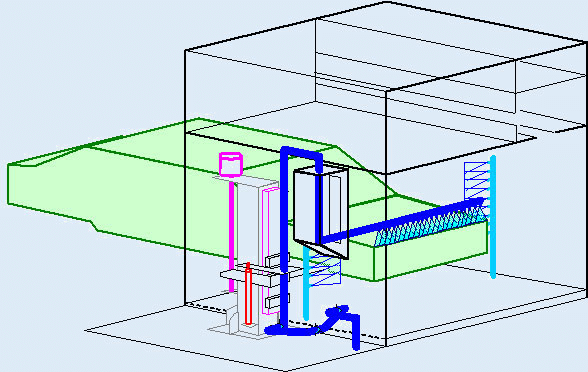

Air conditioners

Taikisha's air conditioning system stably controls the temperature, humidity, and airflow in the painting booth to maintain an optimal environment for painting.

High-precision control technology keeps the quality of the paint film uniform and suppresses the occurrence of defects. In addition, the dehumidification function and effective use of exhaust heat reduce the load on the air conditioning, achieving energy savings. Energy savings and efficient operation also contribute to reducing operating costs.

Technology List

03

Drying Oven

Taikisha's drying ovens are designed to efficiently dry and harden paint films during the painting process. Uniform temperature distribution and stable heat supply prevent unevenness and under-hardening of the paint film, achieving a high-quality finish. Optimizing heating efficiency and air flow also contributes to improved productivity and stable operation. The design reduces unnecessary energy consumption and contributes to reduced operating costs.

Technology List

04

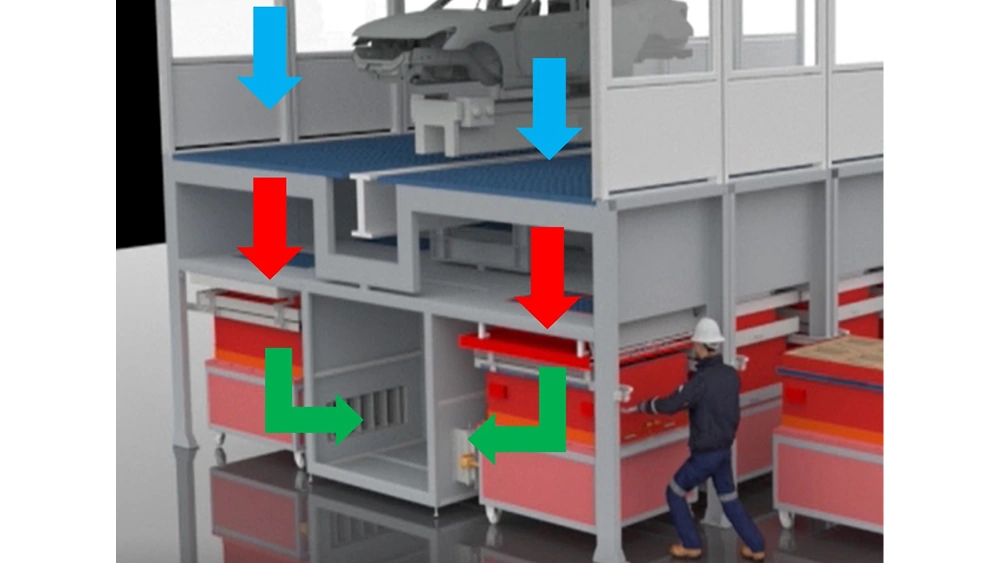

Conveyor equipment

Taikisha's conveyor equipment can handle products of various shapes and sizes, from car and large truck bodies to small precision parts. We provide delivery solutions that can meet various needs.

High stability and durability significantly improve work efficiency and productivity in the painting process.

Technology List

05

IoT System

Taikisha's painting equipment IoT system is a technology solution aimed at improving the efficiency and quality of the painting process.

"i-Navistar" monitors the equipment's operating status and abnormal trends, while "i-TIPS" optimizes work flow and time allocation. Supporting technology- and environmentally-conscious painting.

Technology List

06

Exhaust treatment device

The painting and drying processes generate exhaust gases containing VOCs and unpleasant odors. These emissions require proper treatment.

Taikisha provides exhaust treatment equipment that effectively removes harmful substances generated during the painting process, achieving both environmental protection and a comfortable working environment.

Technology List

Commercial vehicles

Taikisha offers comprehensive support from design to construction for painting equipment for commercial vehicles such as small to large trucks, minivans, full-size vans, route buses, and tourist buses, as well as ambulances, fire engines, garbage trucks, and snowplows.

01

Pretreatment/Electrodeposition Equipment

Pretreatment

Taikisha's pretreatment is an important process for cleaning oil and dirt from metal surfaces with high precision and stabilizing the adhesion of paint, the quality of the coating, and the finish.

Taikisha optimizes energy efficiency and wastewater treatment through technical design that reduces the impact on the environment. In addition, the equipment can be customized to suit a variety of products and line configurations, so it is used at many sites.

Electrodeposition

Taikisha's electrodeposition equipment achieves a uniform, high-quality anti-rust coating film, enabling a finish with excellent durability, adhesion, and beauty.

The unique countercurrent circulation method (C-FLOW) achieves uniform coating film formation even on complex shapes.

With high technical capabilities and equipment design, it is a reliable electrodeposition solution with a proven track record.

Technology List

02

Booths and air conditioners

Booths

Taikisha's painting booths are equipped with temperature and humidity control required for the painting process and a high-performance ventilation system, which effectively expels dust and VOCs generated during painting. This ensures a safe working environment while supporting high-quality paint finishes.

We can design the booth according to the installation environment, work content, and type of paint to be handled, and can design the optimal specifications to meet various needs.

Based on our extensive implementation track record, we can flexibly meet the needs of a wide range of industries and products with customization that combines functionality and reliability.

Air conditioners

Taikisha's air conditioning system stably controls the temperature, humidity, and airflow in the painting booth to maintain an optimal environment for painting.

High-precision control technology keeps the quality of the paint film uniform and suppresses the occurrence of defects. In addition, the dehumidification function and effective use of exhaust heat reduce the load on the air conditioning, achieving energy savings. Energy savings and efficient operation also contribute to reducing operating costs.

Technology List

03

Drying Oven

Taikisha's drying ovens are designed to efficiently dry and harden paint films during the painting process. Uniform temperature distribution and stable heat supply prevent unevenness and under-hardening of the paint film, achieving a high-quality finish. Optimizing heating efficiency and air flow also contributes to improved productivity and stable operation. The design reduces unnecessary energy consumption and contributes to reduced operating costs.

Technology List

04

Conveyor equipment

Pretreatment

Taikisha's conveyor equipment can handle products of various shapes and sizes, from car and large truck bodies to small precision parts. We provide delivery solutions that can meet various needs.

High stability and durability significantly improve work efficiency and productivity in the painting process.

Technology List

05

IoT System

Taikisha's painting equipment IoT system is a technology solution aimed at improving the efficiency and quality of the painting process.

"i-Navistar" monitors the equipment's operating status and abnormal trends, while "i-TIPS" optimizes work flow and time allocation. Supporting technology- and environmentally-conscious painting.

Technology List

06

Exhaust treatment device

Pretreatment

The painting and drying processes generate exhaust gases containing VOCs and unpleasant odors. These emissions require appropriate treatment.

Taikisha provides exhaust treatment equipment that effectively removes harmful substances generated during the painting process, achieving both environmental protection and a comfortable working environment.

Technology List

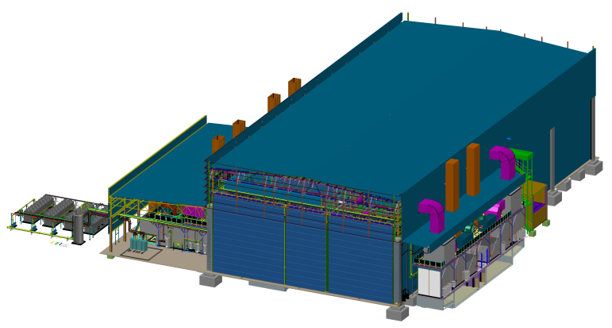

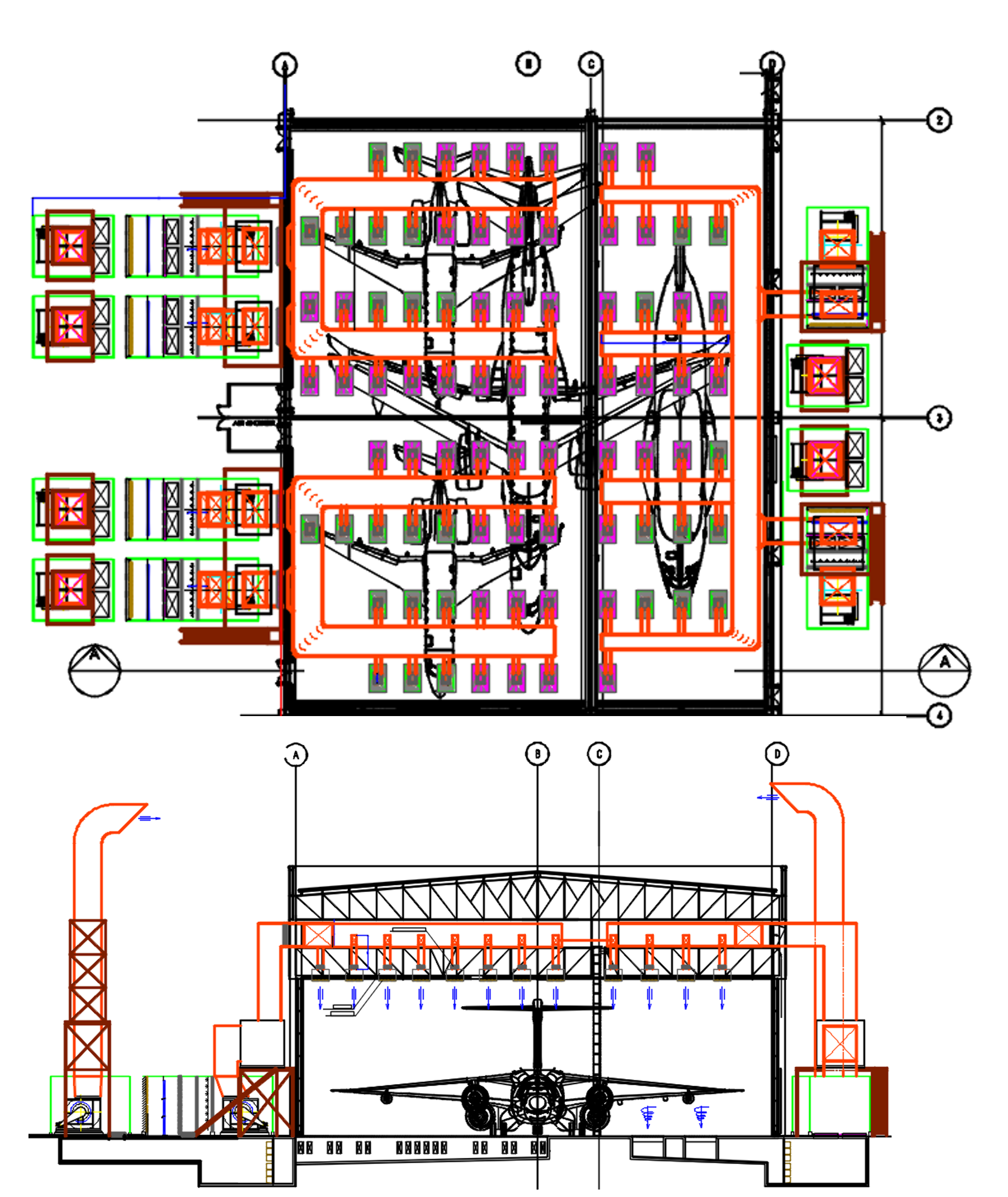

Aircraft

01

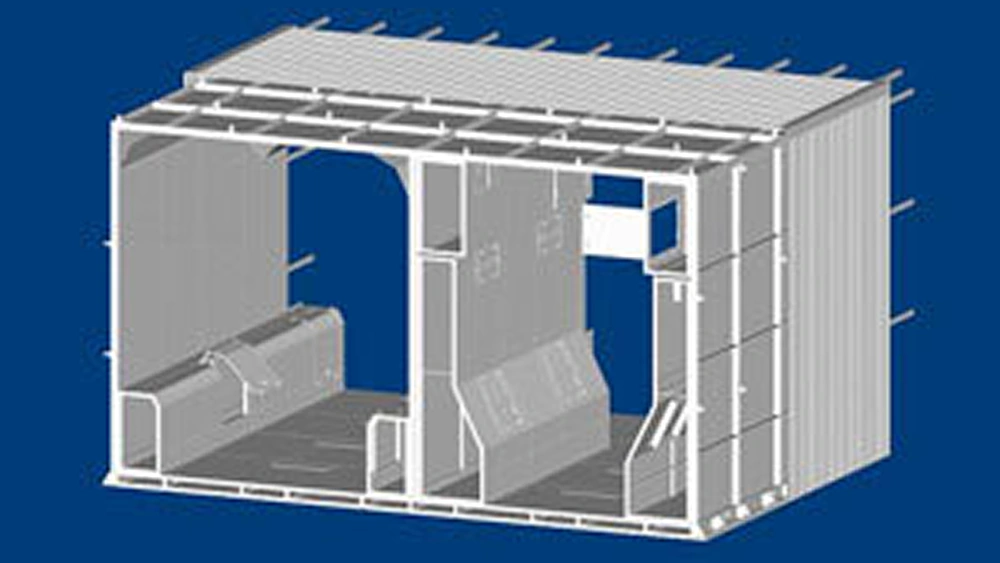

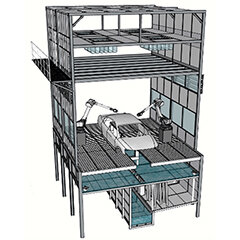

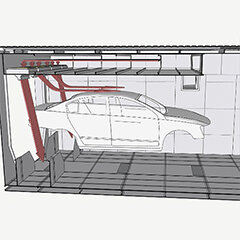

Painting equipment for aircraft

Taikisha is a company that boasts outstanding technology and experience in the design and manufacture of painting equipment for aircraft. Our painting equipment combines the latest technology with high quality to achieve beautiful finishes and durability for aircraft.

Features

- 1.Vast painting space: Equipped with a large painting booth that can handle large aircraft, it achieves efficient and uniform painting.

- 2.Advanced environmental control: Precisely manages temperature, humidity, and airflow to provide an optimal painting environment. We guarantee and pursue a high-quality finish with excellent aesthetics.

- 3.Automation technology: We introduce cutting-edge automatic painting robots to improve work efficiency and provide consistent quality.

- 4.Safety: We have established a thorough safety management system and designed it with the safety of workers as the top priority.

Railway vehicles

01

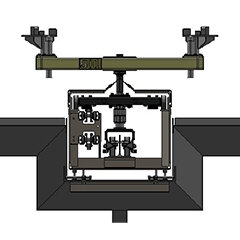

Painting equipment for rail vehicles

Taikisha is a company with a wealth of experience and high technical capabilities in the design and manufacture of painting and sanding equipment for rail vehicle maintenance bases. Our equipment pursues beautiful finishes and durability for rail vehicles, and realizes efficient maintenance processes.

Parts industry

01

Painting equipment for the parts industry

Taikisha is a company with outstanding technology and a proven track record in the design and manufacture of painting equipment for the parts industry. Our painting equipment can handle a wide variety of parts, achieving high-quality finishes and efficient painting processes.

Features Compatible with a wide variety of substrates

- Automobile parts (body panels, bumpers, wheels, interior parts, etc.)

- Motorcycle parts (frames, tanks, exterior plastic parts, etc.)

- Construction machinery parts (chassis, metal exterior parts, etc.)

- Home appliance parts (air conditioner compressors, air conditioner outdoor units, exterior plastic parts, etc.)

- Construction materials (aluminum sashes, door panels, etc.)

- Furniture parts (metal frames, wooden panels, plastic parts, etc.)

- Other industrial parts (machine parts, metal processed products, plastic molded products)

Painting of parts Temporary assembly

Contact

For inquiries or questions regarding this website,

please click on this button.