Automation Business

The future of manufacturing processes made possible by Taikisha's automation technology

Simply collecting robots, peripheral devices, and tools will not improve the efficiency or quality of the entire facility.

As a robot system integrator (robot SIer), Taikisha analyzes the issues at users' sites from multiple angles and designs optimal device configurations and control methods. We provide automation systems that realize highly durable equipment and stable finishes.

For inquiries related to Automation solutions in the US, please visit Encore Automation.

Automobiles

01

Integration Technology

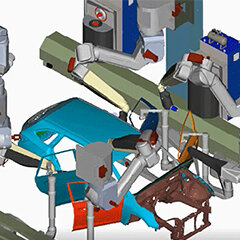

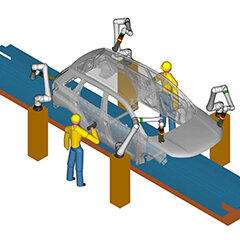

Taikisha offers cutting-edge integration technologies to meet our customers' diverse needs. We utilize three key technologies to optimize the entire system, from the design stage to implementation and operation.

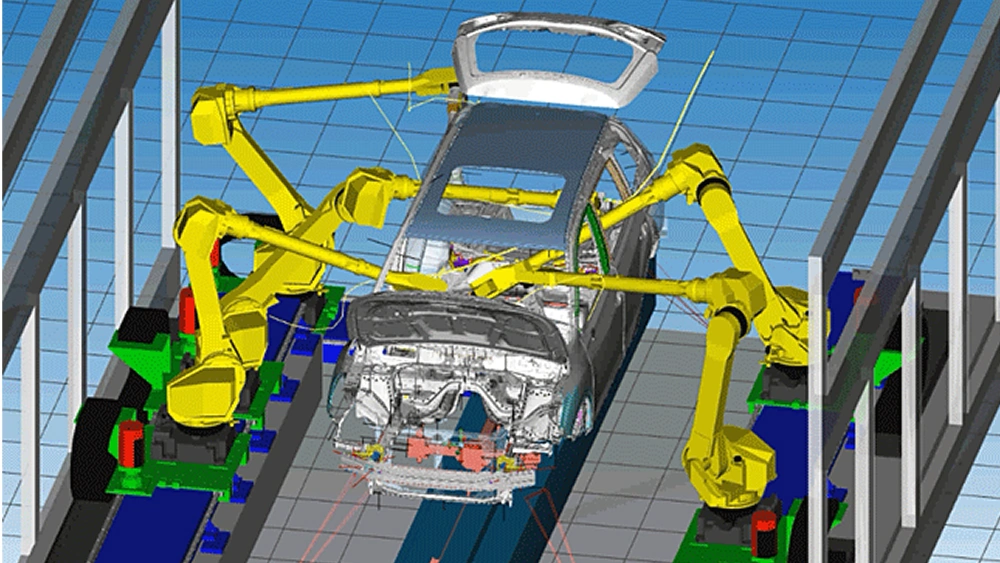

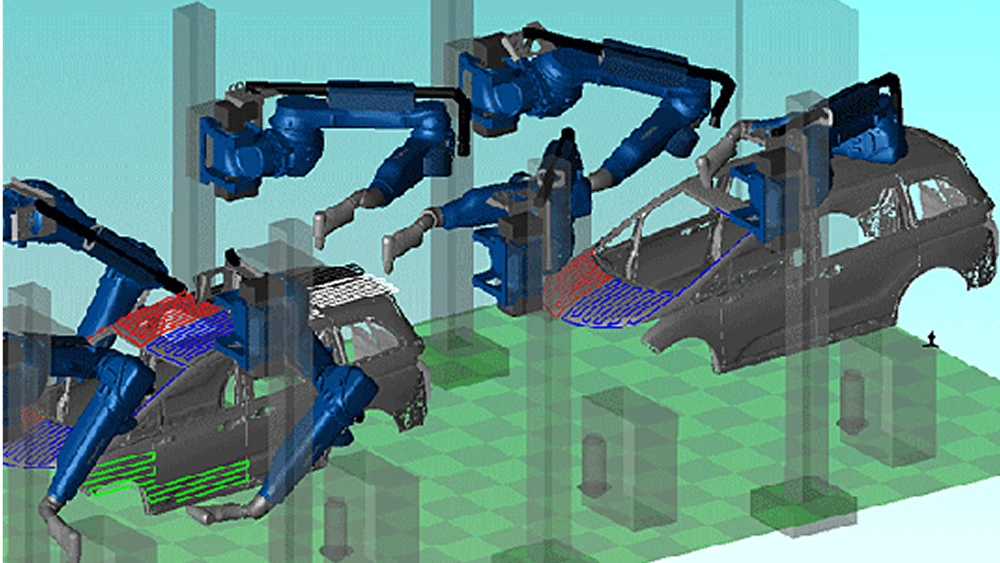

First, we use robot simulation technology to recreate actual production lines in a virtual space, enabling us to verify operation and optimize processes in advance. This prevents problems after implementation and enables efficient equipment design.

Second, we perform pre-assembly and pre-shipment inspections, where we rigorously check quality and safety by assembling and verifying the operation of equipment before delivery. This helps shorten on-site start-up time and ensure stable operation.

Furthermore, we utilize our laboratory to test and evaluate new technologies and products. By verifying our products in an environment that replicates actual production conditions, we provide highly reliable solutions and help resolve our customers' challenges.

By combining these technologies, Taikisha delivers high-quality, optimized integration services, supporting innovation at our customers' production sites.

02

High viscosity dispensing solution

Taikisha provides advanced automation technology and high-performance painting equipment to automate the undercoat process in automobile manufacturing.

This technology aims to achieve high-quality coating while simultaneously improving production efficiency and shortening work time.

Technology List

03

Low viscosity coating solution

The topcoat process is an important process that determines the aesthetics and durability of a vehicle.

At Taikisha, we have built automated systems that are tailored to the characteristics of each part, such as interior panels, which have complex shapes and are prone to uneven painting, and exterior panels, which require a uniform finish.

We achieve stable quality and highly efficient production.

Technology List

04

Material Supply Solutions

Taikisha achieves both productivity and energy saving by suppressing the variation in the quality and finish of the paint film through stable supply of paint materials and high-precision control in the painting process.

Based on many years of experience, we also respond to reducing the amount of paint used and the impact on the environment. We introduce a wide range of technologies and equipment related to paint supply.

Technology List

05

Automated Inspection Solutions

While human inspection is important in the inspection process during the manufacturing process, there are also minute defects and slight irregularities in the coating that are easily overlooked.

At Taikisha, we provide automatic inspection equipment equipped with the latest technology to address such issues.

Technology List

06

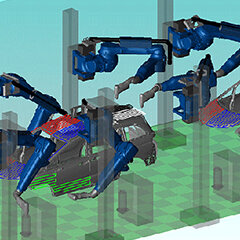

Material Handling

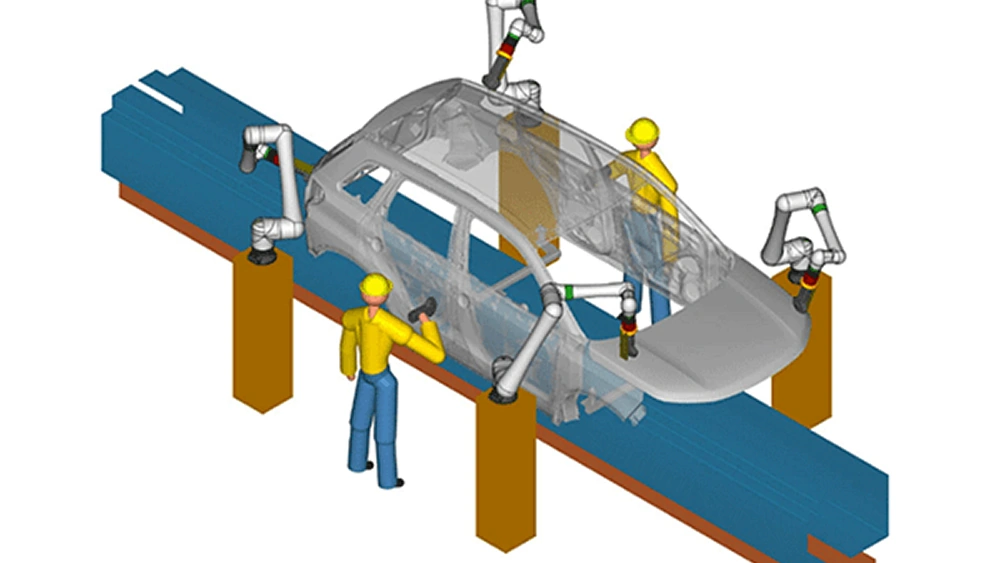

Taikaisha is proactively introducing high-performance equipment and robotics technology to revolutionize the material handling process at manufacturing sites. This initiative aims to improve work efficiency and ensure worker safety, and is expected to have a positive impact on the entire process.

07

Major equipment handled

Taikisha is proactively introducing high-performance equipment and robot technology to innovate the material handling process at manufacturing sites. This initiative aims to improve work efficiency and ensure worker safety, and is expected to have a positive impact on the entire process.

Equipment handled

| Major paint equipment manufacturers | SAMES Co., Ltd., Asahi Sanac Co., Ltd., Atlas Copco Co., Ltd., Graco Co., Ltd., CFT Ransburg Co., Ltd. |

|---|---|

| Major robot manufacturers | Kawasaki Heavy Industries, Ltd., FANUC Corporation, Yaskawa Electric Corporation |

Technology List

Commercial vehicles

01

Integration Technology

Taikisha offers cutting-edge integration technologies to meet our customers' diverse needs. We utilize three key technologies to optimize the entire system, from the design stage to implementation and operation.

First, we use robot simulation technology to recreate actual production lines in a virtual space, enabling us to verify operation and optimize processes in advance. This prevents problems after implementation and enables efficient equipment design.

Second, we perform pre-assembly and pre-shipment inspections, where we rigorously check quality and safety by assembling and verifying the operation of equipment before delivery. This helps shorten on-site start-up time and ensure stable operation.

Furthermore, we utilize our laboratory to test and evaluate new technologies and products. By verifying our products in an environment that replicates actual production conditions, we provide highly reliable solutions and help resolve our customers' challenges.

By combining these technologies, Taikisha delivers high-quality, optimized integration services, supporting innovation at our customers' production sites.

02

High viscosity dispensing solution

Taikisha provides advanced automation technology and high-performance painting equipment to automate the undercoat process in automobile manufacturing.

This technology aims to achieve high-quality coating while simultaneously improving production efficiency and shortening work time.

Technology List

03

Low viscosity coating solution

The topcoat process is an important process that determines the aesthetics and durability of a vehicle.

At Taikisha, we have built automated systems that are tailored to the characteristics of each part, such as interior panels, which have complex shapes and are prone to uneven painting, and exterior panels, which require a uniform finish.

We achieve stable quality and highly efficient production.

Technology List

04

Material Supply Solutions

Taikaisha achieves both productivity and energy saving by suppressing the variation in the quality and finish of the paint film through stable supply of paint materials and high-precision control in the painting process.

Based on many years of experience, we also respond to reducing the amount of paint used and the impact on the environment. We introduce a wide range of technologies and equipment related to paint supply.

Technology List

05

Automated Inspection Solutions

While human inspection is important in the inspection process during the manufacturing process, there are also minute defects and slight irregularities in the coating that are easily overlooked.

At Taikisha, we provide automatic inspection equipment equipped with the latest technology to address such issues.

Technology List

06

Material Handling

Taikaisha is proactively introducing high-performance equipment and robotics technology to revolutionize the material handling process at manufacturing sites. This initiative aims to improve work efficiency and ensure worker safety, and is expected to have a positive impact on the entire process.

07

Major equipment handled

Taikaisha is proactively introducing high-performance equipment and robot technology to innovate the material handling process at manufacturing sites. This initiative aims to improve work efficiency and ensure worker safety, and is expected to have a positive impact on the entire process.

Equipment handled

| Major paint equipment manufacturers | SAMES Co., Ltd., Asahi Sanac Co., Ltd., Atlas Copco Co., Ltd., Graco Co., Ltd., CFT Ransburg Co., Ltd. |

|---|---|

| Major robot manufacturers | Kawasaki Heavy Industries, Ltd., FANUC Corporation, Yaskawa Electric Corporation |

Technology List

Aircraft

01

Robotic painting for aircraft

Taikisha's automation business is Combining painting technology and robot control technology that we have cultivated over many years, We provide high-quality, highly efficient robot solutions for the painting process in the aircraft industry.

Aircraft painting is a field that requires advanced technology, as it can handle large structures, complex shapes, and strict quality requirements.

Taikisha achieves both stable quality and future productivity through automation design that takes the entire process into consideration.

Five features of Taikisha's automation

Reduce quality variations

Stabilizes working conditions and operations to achieve consistent quality every time

Automation that takes the entire process into consideration

We design equipment, operations, and the environment as a whole

Creating a system with an eye to the future

Addressing issues of labor shortages and skill transfer

Reducing environmental impact

Optimal use of paint and mist suppression minimizes environmental impact

Improved work safety

The painting process does not require working at height, ensuring worker safety.

Railway vehicles

01

Robot painting for railcars

Taikisha's automation business is Combining our long-cultivated painting technology with cutting-edge robot control technology, We provide high-quality robot solutions for the painting process of railway vehicles.

The painting of railway vehicles is an area that requires a consistent finish, with large car bodies, long structures, and complex shapes, as well as high appearance quality and durability. Taikisha's robotic painting system addresses these challenges, realizing an efficient, highly repeatable painting process with reduced quality variation.

Five features of Taikisha's automation

Reduce quality variations

Stabilizes working conditions and operations to achieve consistent quality every time

Automation that takes the entire process into consideration

We design equipment, operations, and the environment as a whole

Creating a system with an eye to the future

Addressing issues of labor shortages and skill transfer

Reducing environmental impact

Optimal use of paint and mist suppression minimizes environmental impact

Improved work safety

The painting process does not require working at height, ensuring worker safety.

Parts industry

01

Robotic painting for the parts industry

Taikisha's automation business handles painting of a wide variety of shapes, specifications, and lot sizes, from large structures to small parts. Even in special coatings that require design and functionality, by optimally controlling the amount of coating, coating distance, and operation, we can achieve consistent quality that would be difficult to achieve by hand, providing a uniform, highly reproducible finish.

In addition, Taikisha's Thailand Technical Center has We are equipped with the latest equipment for painting parts, and are able to carry out on-site painting tests.

Through tests using actual parts, we confirm the quality of the finish and propose optimal painting conditions.

Five features of Taikisha's small item painting

1. Reduced quality variations

The application amount, distance, and movement are optimally controlled to achieve a consistent, even finish.

2. Handling of complex shapes and small parts

High-precision robotic painting is possible even for intricate shapes and small parts.

3. Flexible response to high-mix, small-lot production

We have established a painting process that can flexibly accommodate products with different lot sizes and specifications.

4. Support for decorative and functional coatings

We also handle decorative painting that emphasizes appearance quality and special painting that adds functionality.

5. Environmentally friendly painting process

By optimizing the amount of paint used and mist generation, we can achieve a painting process that contributes to reducing the environmental impact.

Thailand Technical Center Equipment

Contact

For inquiries or questions regarding this website,

please click on this button.