TAIKISHA (THAILAND) CO.,LTD TECHNICAL CENTER ASEAN

A center for creating the future of coatings with cutting-edge technology

We are capable of coating tests on parts up to 2,000W x 1,000L x 1,000H.

We also have a transportation system, allowing us to conduct coating tests in a variety of situations.

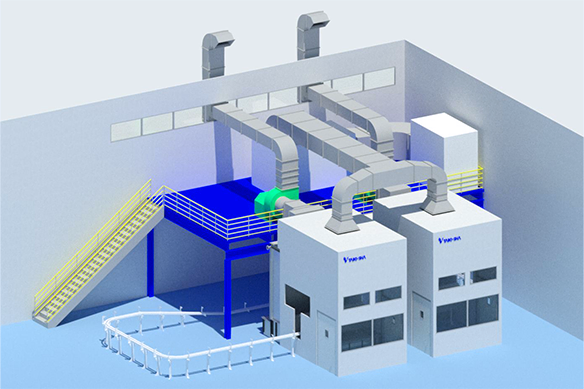

Facility Overview

Our technical center is located in the Technical Center Building adjacent to our can manufacturing plant.

| Name | TAIKISHA (THAILAND) CO., LTD |

|---|---|

| Address | 445 M.17 Bangsaothong, Samutprakarn 10540 |

| Tel | 065-986-4167 |

| pfasean.grp@tikisha.co.th | |

| Equipment | Two booths and painting robots (dry and wet), one batch drying oven, and one conveying device |

Equipment details

Our Technical Center is equipped with one dry (cardboard filter) booth and one wet booth.

We have installed a booth robot, which allows us to perform bell coating and air gun coating tests.

The transport can be switched between continuous (high speed, low speed), index rotation, and continuous rotation, allowing us to perform coating tests in a variety of situations.

Our batch drying oven allows for drying tests at temperatures from low to 160°C.

As our facility is located next to a can manufacturing factory, we can manufacture painting jigs on-site.

Spray Booth Specification

| Description | Dry Booth | Pumpless Booth |

|---|---|---|

| Dimension Air Velocity(m/s) Exhaust Volume(m3/min) Exhaust Type Illumination(LUX) |

3.0 mW x 4.5 mL x 4.0 mH 0.25 - 0.4 180-290(Adjustable) Cardboard Filter 800 |

3.0 mW x 4.35 mL x 4.0 mH 0.25 - 0.4 180-290(Adjustable) Pumpless Scrubber 800 |

Robot Painting Specification

| Description | Booth No.1 | Booth No.2 |

|---|---|---|

| Robotics Bell Air Gun Gear Pump Color Change Valve Paint Application Software |

Yaskawa: MPX-3500-00A1 PPH70758,(Sames) T2AGPV-A76-805MT2-FX,(Devilbiss) Taikisha Taikisha Taikisha |

Kawasaki:KJ264JFE25 TAR300-11,(Taikisha) T2AGPV-676-805MT2-FA,(Devilbiss) Taikisha Taikisha Taikisha |

Conveyor Specification

| Description | System |

|---|---|

| Conveyor Type Conveyor Speed Rotation Parts Change Rotation Direction Parts Painting station style |

Power & Free Floor Conveyor Low Speed: 1 m/min, High Speed: 16 m/min 20 - 72 rpm. Clockwise > Counter Clockwise, Counter Clockwise > Clockwise Adjustable: 1. Continuous 2. Continuous Part Rotation 3. Stop&Go, 90 Rotation 4. Stop&Go, Spindle Rotation |

Oven Specification

| Description | System |

|---|---|

| Dimension Setting Temperature Heat Source |

2.0 mW x 2.3 mL x 1.8 mH 70°C-160°C Electric Heater 60 KW |

Contact

For inquiries or questions regarding this website,

please click on this button.