Overhead Conveyor Mono-Track Conveyor

- Conveyor equipment

- Conveyor equipment

Taikisha's Technology

What is our conveyor systems?

The conveyor system in the painting factory is an automatic transportation system that is involved in the entire process from receiving the car body from the welding factory, passing through the painting process, and handing over the car body to the assembly factory. Taikisha supports various transportation systems, from the hanger / trolley method that has been used in Japan for a long time to the skid method that is mainly used in Europe. In addition, it can be used not only for automobile bodies but also for painting systems for plastic parts.

What is undercoating overhead conveyors?

Overhead conveyor is used in the undercoat process.

Overview

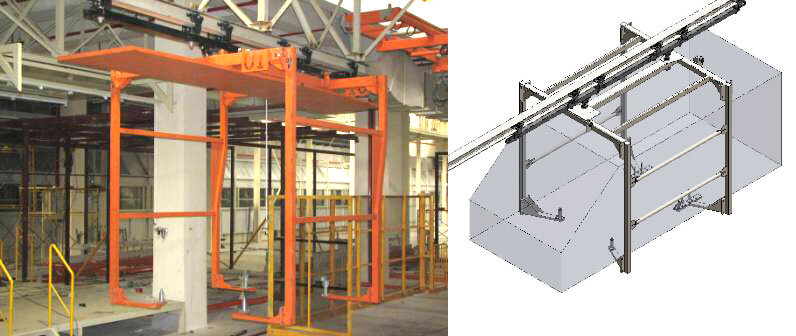

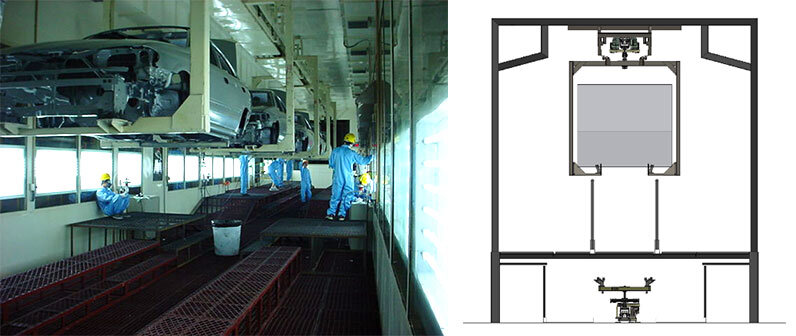

This conveyor is a hanger type overhead conveyor applied to the undercoat process. It is a friction type transport and is a tact type (continuous type is also possible). It can also be used in robot processes. Both fixed and openable hangers are available.

Hanger (Ficed type)

Inside the process

Features

①Using a friction system allows high-speed movement. Low-speed continuous movement is also possible.

②The friction system can increase energy efficiency by operating only when the hanger is detected.

③The line makes it possible to save space because it combines lifting and transport.

④Adopting a friction system can reduce the noise of operation.

Contact

For inquiries or questions regarding this website,

please click on this button.