Dry Film application

What is the dry film system?

Amid a global shift to carbon neutrality, the automotive industry is now undergoing a period of great change. With an eye on the CO2 emission reduction targets of each automobile manufacturer, we are challenging ourselves to develop and innovate the painting process in order to achieve carbon neutrality in paint factories.

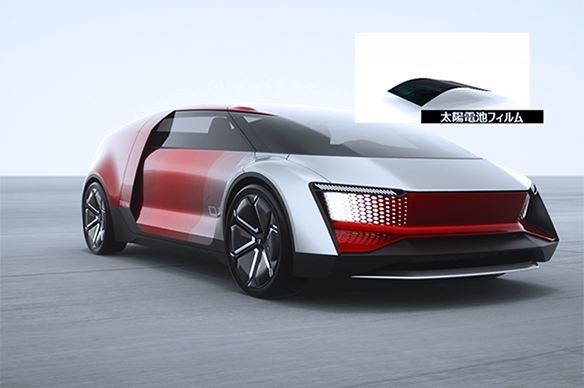

As part of this effort, we are promoting the innovation of production methods from wet painting to dry film. Instead of the conventional spray painting (wet painting), the new method of decorating by attaching a film is a new method that dries the process and reduces the burden on the environment. In addition, by suppressing unevenness during painting and reducing the drying process, it is expected to have benefits such as improved quality and finish, and shorter production time.

What are OMD (Out-Mold Decoration) and IMD (In-Mold Decoration) systems?

There are four methods for decorating automotive exteriors with film: out-mold decoration (OMD), in which a film is laminated or transferred onto a molded product after the fact, and in-mold decoration (IMD), in which a film is laminated or transferred onto a molded product at the same time as resin injection molding.

Depending on the material, shape, decoration range, and production capacity of the molded product, we will propose the optimal method and automated process line, taking into consideration stable quality, beautiful finish, equipment efficiency, etc.

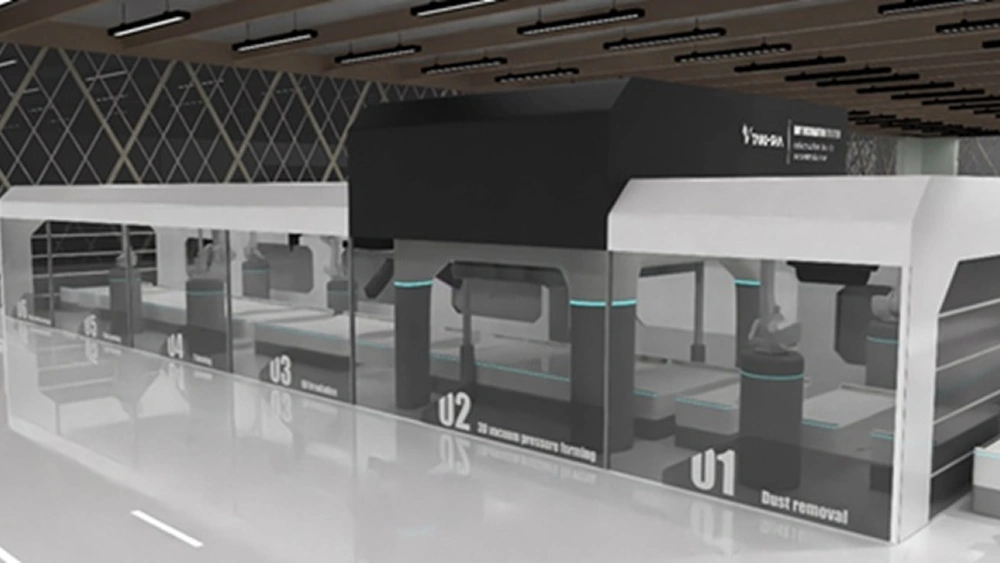

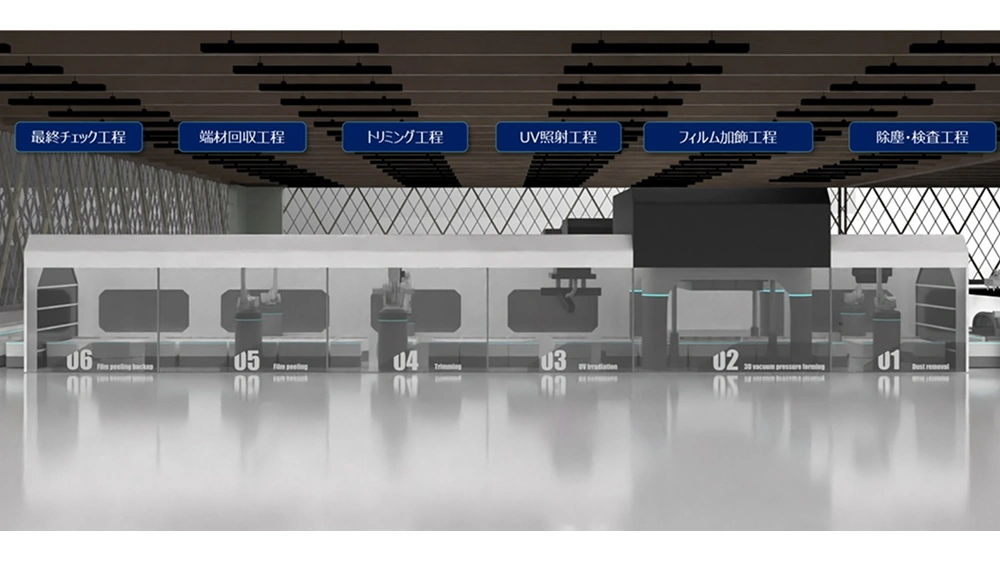

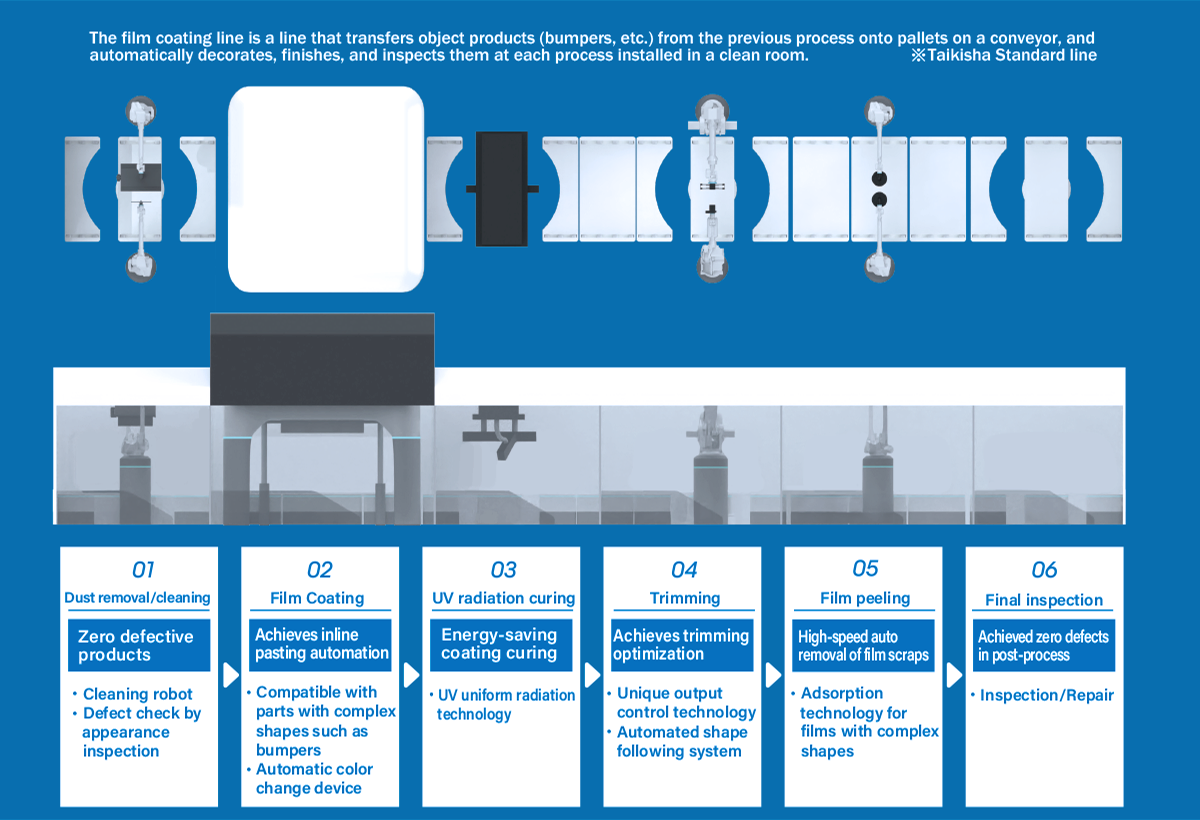

Overview

The dry film line is a facility that transfers the target products (bumpers, etc.) transported from the previous process onto pallets on a conveyor, and performs automatic decoration, finishing, and inspection at each process installed in a clean room.

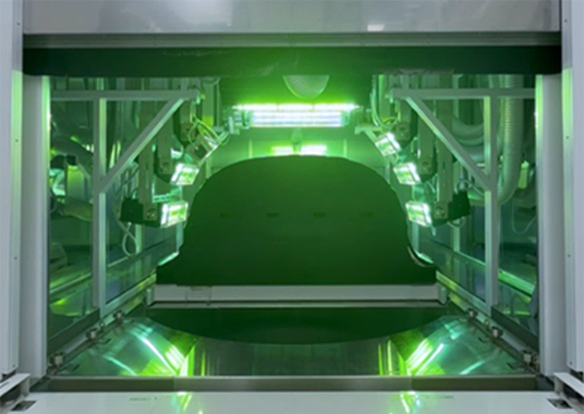

The products placed on the pallets are first cleaned to remove foreign objects and debris, and a film is attached using vacuum and compressed air technology. Depending on the layer structure and specifications of the film, a hardening process such as UV irradiation is performed after attachment to increase durability. In the next process, the film attached to the product is trimmed and finished, and any remaining film scraps other than the product are collected.

Finally, the attached film-decorated products are inspected to confirm their quality before being transported to the assembly process. After the products are de-decorated, the pallets are returned to the arrival area by the return line.

Features

The dry film system can apply film to large, three-dimensional exterior parts such as bumpers in a continuous line, and can also be used on resin and steel products.

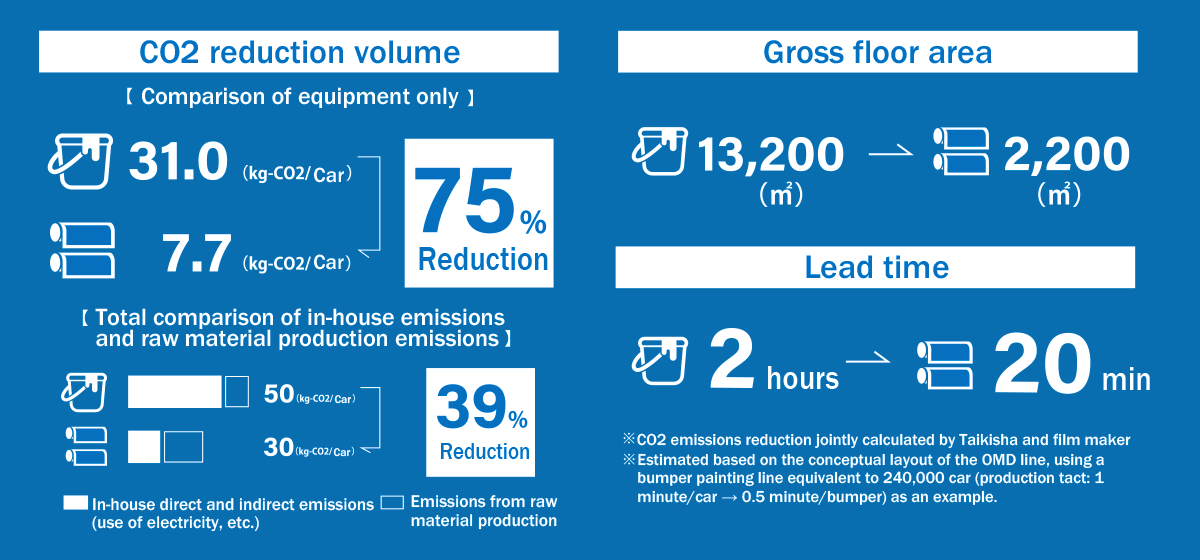

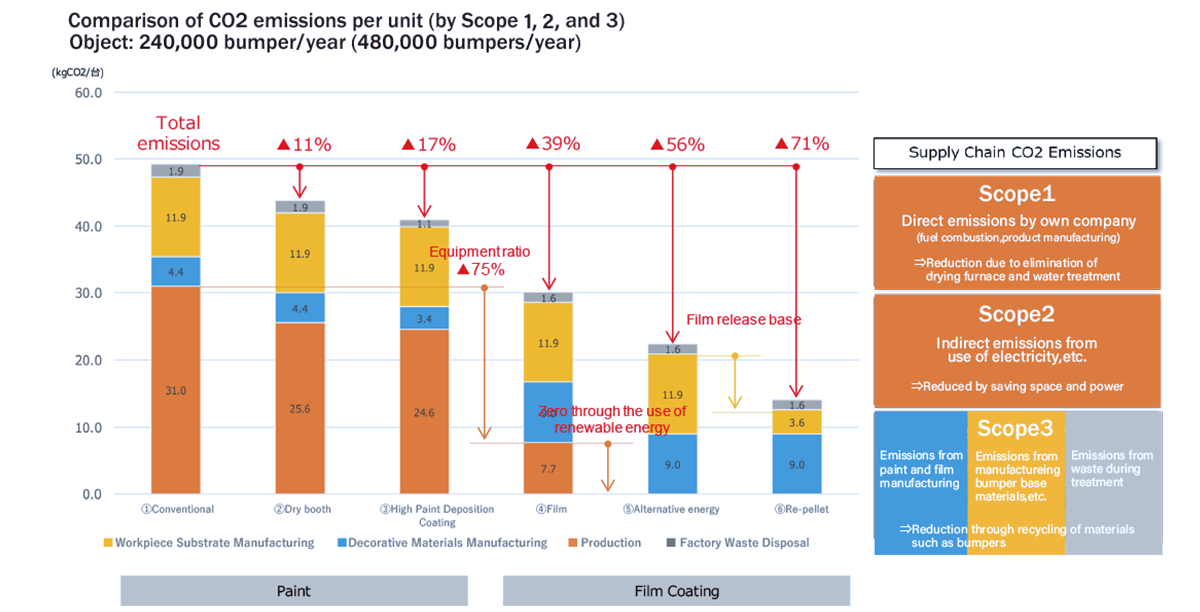

The adoption of a dry film line makes it possible to significantly reduce CO2 and energy consumption compared to conventional wet painting, and also reduces the impact on the environment.

Since there is no need for large equipment such as booths, air conditioning, drying ovens, drainage equipment, and paint circulation equipment required for wet painting, equipment costs and installation space can be reduced.

Another major feature is that the film's unique design (patterns, designs, illumination) and functionality (solar cells, heat insulation) make it possible to create expressions that were not possible with conventional painting.

Effect

Introduction video

Device image

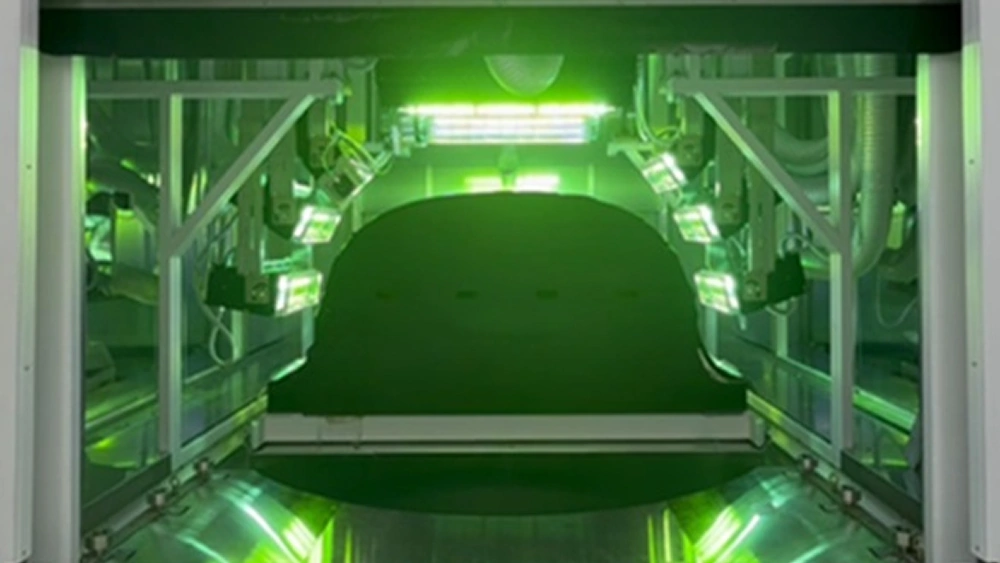

Vacuum forming equipment

Trimming process

UV irradiation process

Waste material recovery process

Contact

For inquiries or questions regarding this website,

please click on this button.