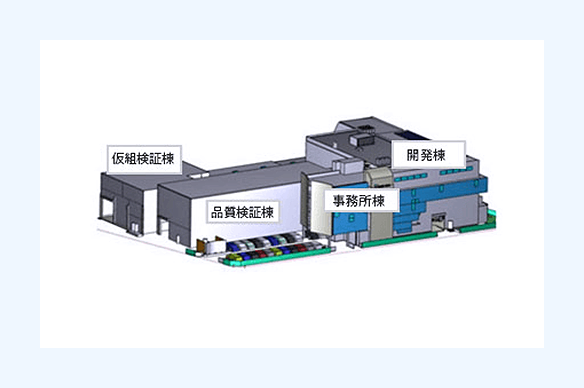

Technical Center Zama

A hub for creating the future of painting with cutting-edge technology

In the development building within the technical center, we develop painting systems for automobiles, as well as polishing and painting systems for railway vehicles, aircraft, and small products.

In the quality verification building, we conduct experiments based on painting simulations using painting robots, various painting equipment, and a variety of body types and paints.

We pursue the overall quality and optimal effectiveness of the painting system using booths, flash-off equipment, and ovens.

Furthermore, in the pre-assembly verification building, we assemble each component and conduct operational confirmation tests before shipment to ensure the functionality, operation, and quality assurance of the delivered system. We conduct thorough verification work to provide our customers with peace of mind.

Facility introduction

The technical center facilities consist of four buildings: an office building, a development building, a quality verification building, and a prototype assembly verification building.

Technical Center Details

-

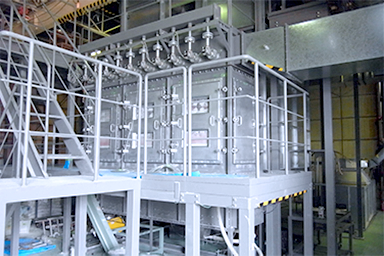

Integrated verification booth equipment

This facility enables comprehensive evaluation of the overall painting system—including the behavior of paint mist inside the spray booth under various air-supply conditions such as those used in the i-LAVB (Low-Air-Volume Booth), contamination of painting robots caused by airflow disturbances during coating, performance evaluation of exhaust dust removal devices, and maintainability.

The i-LAVB is a spray booth that controls the airflow—traditionally uniform—into an airflow optimized for painting, allowing air volume to be reduced by up to 30%.

-

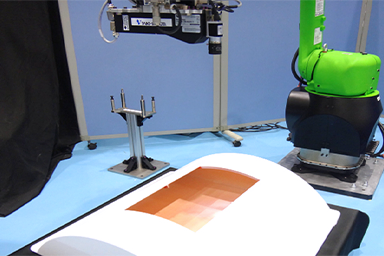

i ART (Automatic Teaching System)

The i-ART (Automatic Teaching System) is a technology that automatically generates robot operation programs based on images captured by a 3D sensor. This significantly reduces the labor previously required for teaching work and contributes to manpower reduction and quality improvement by enabling highly accurate and stable robot operations.

Furthermore, by combining this with matching technology using 2D camera images, it is also possible to generate robot motions based on criteria such as color variations and painting defects.

Compared to conventional manual polishing and painting, it also offers the significant advantage of achieving a uniform, streak-free finish.

-

Dry decoration system

Dry decoration is a new film-based decoration technology that serves as an alternative to conventional spray painting. It reduces CO₂ emissions and enables efficient, environmentally friendly decoration. In addition, it makes it possible to create high value-added products unique to film-based processes.

Our dry film system supports decoration on large three-dimensional components, such as bumpers, through our proprietary vacuum and pressure forming technology.

At our Technical Center, all processes—from forming and trimming to scrap collection—can be performed automatically. Through prototyping, we can provide the optimal proposals tailored to our customers’ requirements.

-

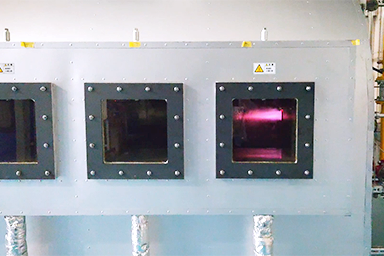

Hydrogen combustion drying equipment

As part of our efforts to hydrogenate heat sources in drying furnaces, we are equipped with facilities to verify the performance and safety using actual hydrogen burners. To establish an optimal system that minimizes environmental impact, we check the basic performance, applicable regulations, and safety measures of various hydrogen gas burners that correspond to CN heat sources.

© Iwatani Corporation / Sunray Refrigeration & Heating

-

Pre-coated dry oven

This is a dry paint booth that combines a pre-coating agent with a high-performance filter.

Unlike conventional wet booths, it does not use any water, making it highly effective even in regions with limited water resources.

Furthermore, when reusing exhaust air, no dehumidification process is required, resulting in significantly improved energy efficiency and potential cost savings compared to wet booths.

-

i Dry Scrubber (Cardboard filter type dry booth)

This is a dry paint booth that removes dust using disposable dry filters (cardboard filters).

Since dust removal is achieved with only a few stages of filters, the system configuration is simple.

As with the pre-coating type, it does not use any water, making it highly effective in regions with limited water resources.

Furthermore, when reusing exhaust air, no dehumidification process is required, resulting in significantly improved energy efficiency and potential cost savings compared to wet booths.

Quality Verification Building

-

Painting line

This facility is equipped to operate two booths simultaneously and is the only one in East Asia capable of testing water-based paints and 3-wet painting methods using actual vehicle bodies.

The booths feature technology that allows for flexible adjustment of airflow speed and a wide range of booth air temperature and humidity settings. This enables high-precision verification of paint film quality, finish variations, and the effects of drying conditions.

-

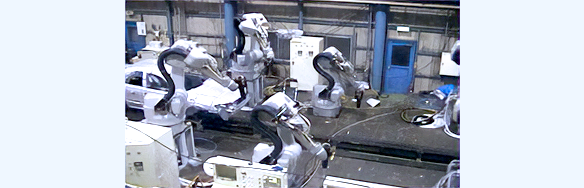

Painting robot

It is possible to conduct painting tests using the same painting robots and applications as those used on the actual production line.

The teaching programs used in the painting tests can be smoothly transferred to the actual production line.

-

Oven

The flash-off device, designed to accommodate diverse environmental conditions, allows for verification of robotic painting with water-based and 3-wet paints.

The baking oven enables baking processes using actual car bodies, allowing for confirmation of paint quality, including finish and durability.

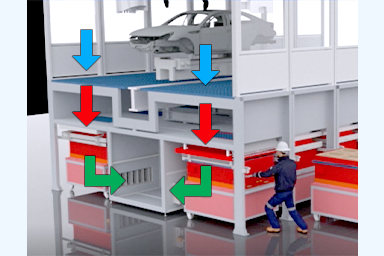

Temporary Assembly and Verification Building

To check the final finish, we perform a trial assembly of each part.

We conduct functional and operational tests to check the function, operation, and quality before shipment.

Contact

For inquiries or questions regarding this website,

please click on this button.